Premier is a global leading manufacturer of American-made plastic pallets. See our large inventory of low-cost skid/pallets for sale at wholesale pricing. Our pallet specialists are here to assist you in buying the right pallet. We carry a large inventory in stock and ready to ship. PHS Inc. is located in Elgin, Illinois, near HWY I-90 and 40 minutes west of Chicago, IL.

Showing all 90 results

Premier Is A Leading Plastic Pallet Manufacturer

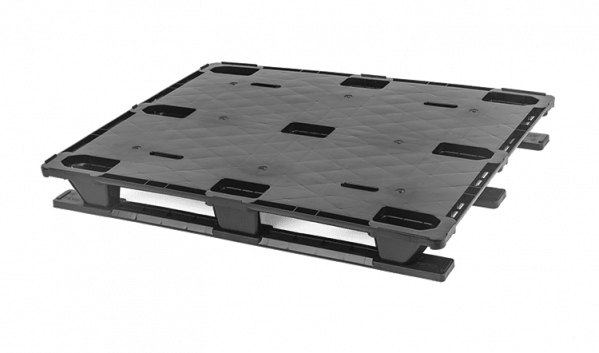

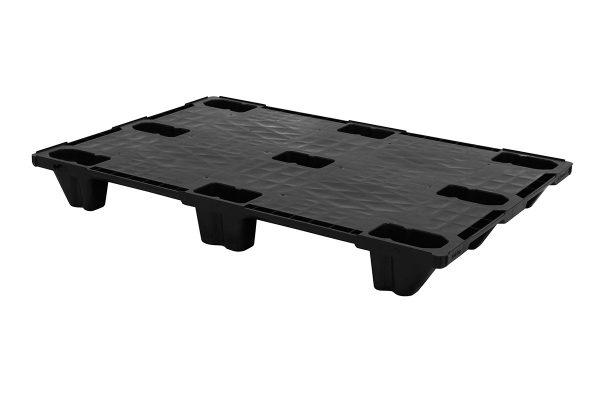

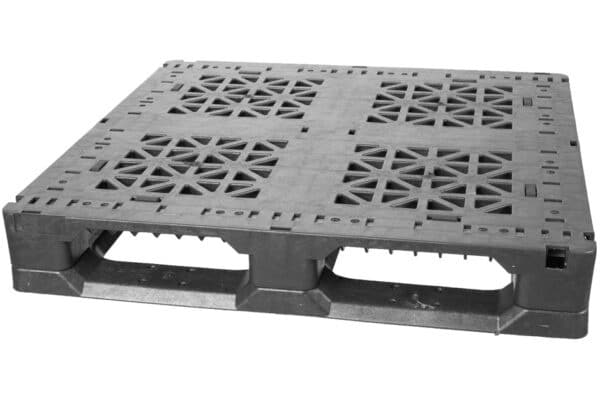

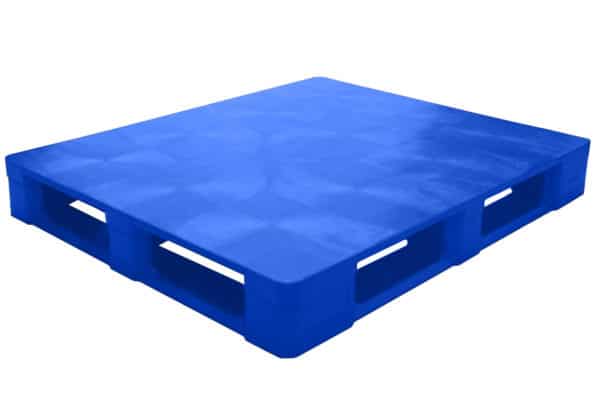

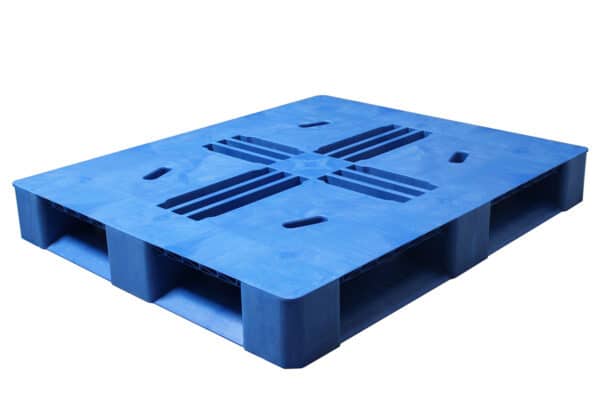

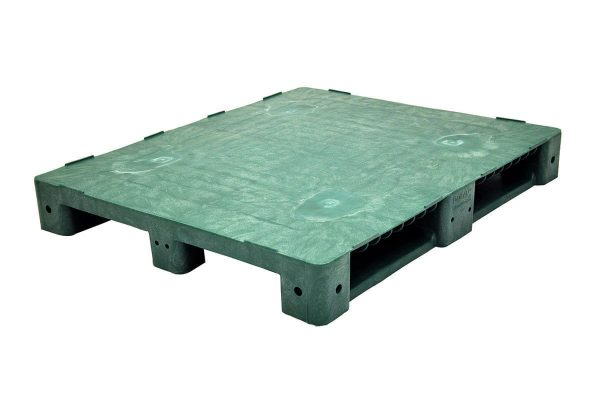

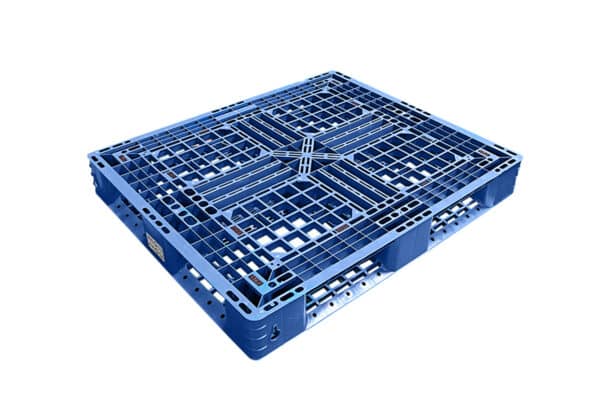

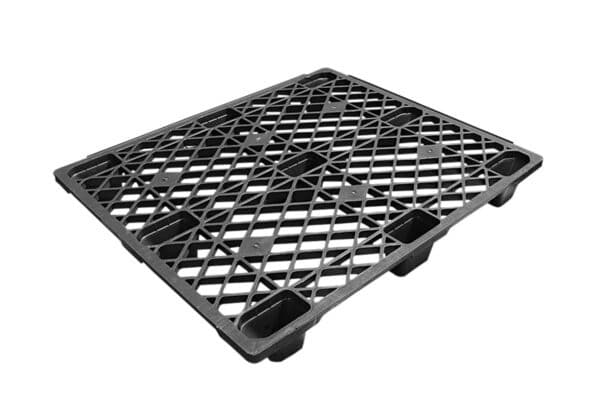

We offer a diverse range of pallets, from export to rackable, stackable, and nestable, ensuring the ideal solution for every requirement. Each pallet is crafted from premium materials, designed to endure heavy loads. With our swift shipping, your products reach the market promptly. Spanning from California to North Carolina, Premier has got you covered.

Our main pallet suppliers division, PHS Inc., is strategically situated in Elgin, Illinois, close to HWY I-90 and just 40 minutes from Chicago.

With the expertise of our engineers and technicians, we’ve crafted durable plastic pallets built for the demanding nature of shipping. Our design considerations range from stackability and weight distribution to overall robustness, ensuring each pallet matches your specifications. And as we aim for perfection, our designs evolve to meet ever-changing industry demands.

At Premier, we realize how crucial it is to choose the right pallet. To dispel any myths about plastic pallets and ensure you make an informed decision, our plastic pallet specialists are at your service. Whether you’re after standard sizes or need customization, we’ve got a pallet to fit your operations. Lean on our experienced team for guidance on the optimal pallet for your needs.