HAND WASHING STATIONS

- Description

- Clean Room Glossary

Premier Hand Washing/ Disinfection Stations

Premier is a leading manufacturer of hand washing stations in the USA. Each hygienic automatic washer is industrial grade and used primarily in restaurants and food industries. Our hand washing stations for sale are heated, self contained, and can be used for 4 person or even groups. Our sensor-operated metal wash basins automatically starts to flush water through its pipes when not in use, which helps remove bacteria from it that could cause illness such as Legionnaire’s Disease or Pontiac Fever. It can be programmed to flush up to 24 hours if there was no previous interaction; but for those who want an extra measure of safety against harmful germs, you have the option for it only take 12 days before starting another cycle again!

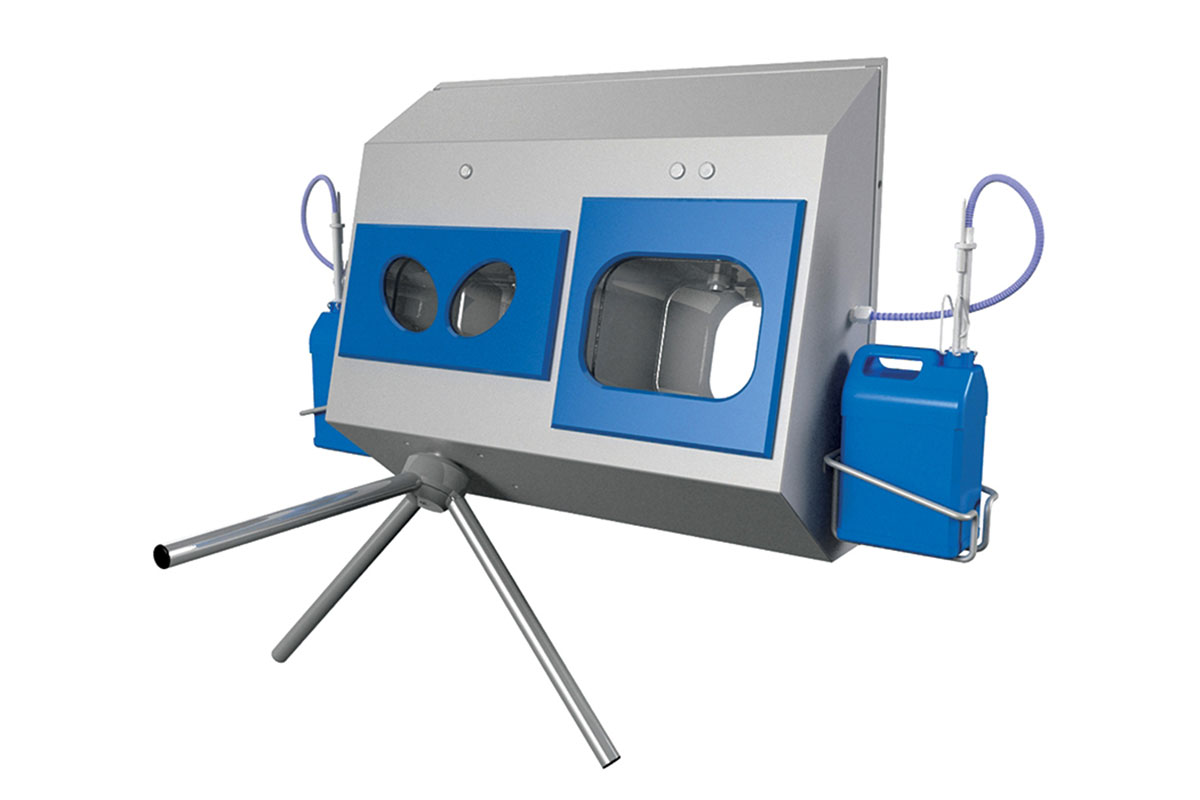

A stainless steel industrial sink can greatly reduce the risk of contamination before entering production areas. Place the unit on a flat surface and simply insert your hands into the openings. Sensors will automatically activate the disinfectant (no hand crank needed). Premier supplies large and small mounted wash basins that mount to a wall as well as portable hand disinfection stations.

Premier hand washing systems are the perfect compliment to any cleanroom entrance procedure and our portable hand disinfection stations make sterilization quick and easy.

Call an industry expert today at (800) 404-2311.

Clean Room Glossary

Clean Room- a Cleanroom is a controlled environment that uses HEPA filtration to remove particles from the air. Cleanrooms are used for the manufacturing or assembly of objects that are required to maintain a high level of cleanliness.

Doffing- The process of removing an item of PPE to ensure that a person does not become contaminated.

Donning- The process of putting on a piece of PPE to ensure they do not become contaminated when entering a sterile environment.

PPE (Personal Protective Equipment)- Equipment that is worn by an individual to minimize the exposure to hazards that may cause injury or contamination. This includes such things as clean room suits and protective gloves.

Cleanroom Classification- Cleanrooms are classified based on the number of contaminants that exist within a cleanroom. This is determined by the number of particles in the air that are greater than .5 microns in size within 1 cubic meter of a cleanroom. Classifications are based on ISO Standards.

ISO Standards (Clean room Classifications)- ISO (International Standards Organization) Standards is broken down into nine ISO classes. The lower the class the cleaner the environment. The most common ISO classes for clean rooms are ISO 7 and ISO 8.

HEPA Filter- HEPA is an acronym that stands for “High Efficiency Particle Air [Filter]”. These types of filters are used to remove close to 99.97% of any airborne particles greater than 0.3 microns.

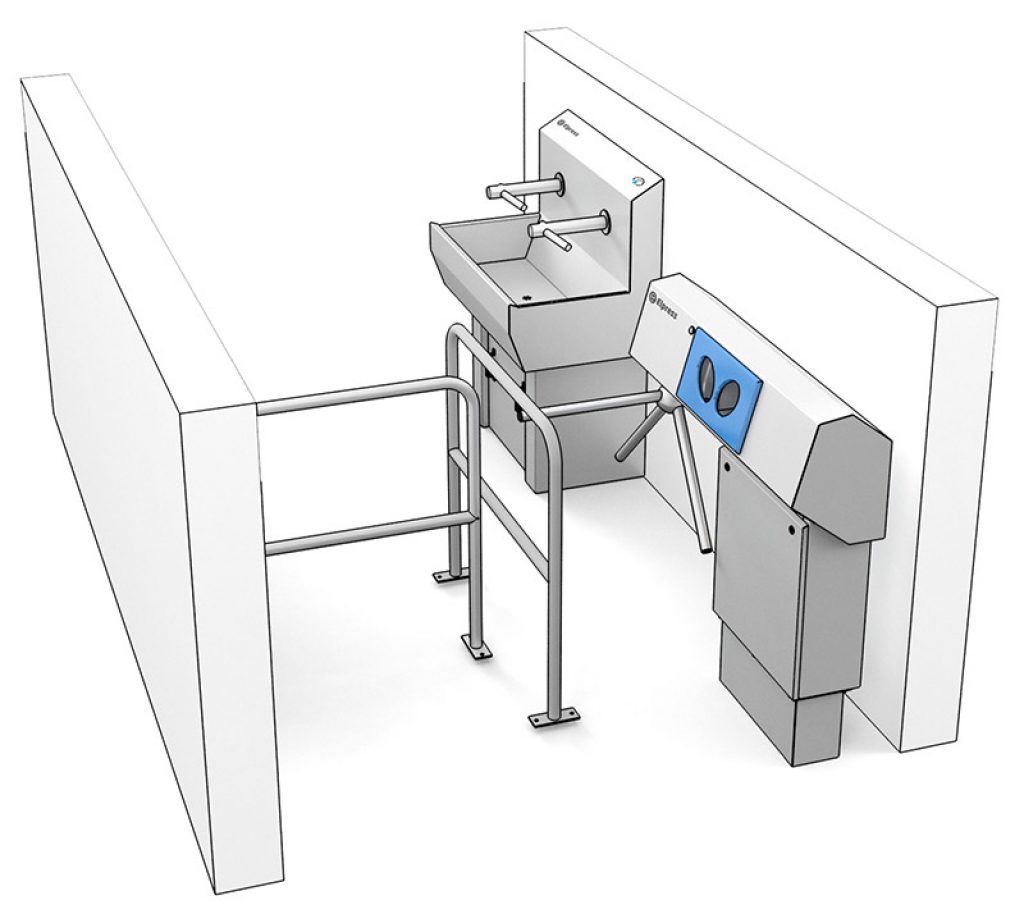

Access Gate Control Hygienic Entrance

Premier recommends the use of a turnstile, i.e an entrance gate to ensure that all employees are meeting all mandatory hygiene requirements for your clean room classification. The use of an entrance gate has many advantages:

Controlled Access: Staff members must wash their hands and disinfect them before entering the production area. For safety reasons, they are not granted access without doing so first.

Contactless Soaping and Disinfecting: Our HDT/HST sprays soap or an antiseptic on your hands. This prevents the risk of infection because there’s no contact with germs whatsoever.

Required Unlock Procedure: Both hands must be inserted into our chemical dispensers in order to release the turnstile.

Longer Chemical Contact Time: The turnstile is unlocked and the employee may pass through. This takes a few seconds which makes sure the soap or disinfectant has a longer time of contact with the employees hands.

Controlled Chemical Use: The sensors in the chemical dispensers ensure that employees use just enough chemicals required. In addition, we need to refill these containers less often because a 5-litre canister is always being used. If an employee runs out of soap or disinfectant they cannot enter the production area and will know not have access again until it’s refilled by someone else.

What customers Say About

Premier

About Premier Handling Solutions

“Industry Proven Solutions”

Premier Handling Solutions is a leading manufacturer that proudly provides American-made machines and tools to material handling and supply-chain industries. We provide warehouse equipment solutions that improve overall productivity, safety, and speed throughout the manufacturing, warehousing, distribution, consumption, storage, and disposal process.

Our products span from pallets, inverters, tippers, wire containers, pallet dispensers, pallet jacks, and lift tables, to safety accessories, hygiene tools, freezer spacers, and beyond. Ship and store products like food and pharmaceuticals safely, with PHS pallets and containers. With Premier Handling Solutions, businesses maximize the use of their warehouse and facility spaces and optimally manage HACCP programs.

PHS products uphold top industry standards and meet required government compliance and regulations.

Quick Menu

Location

Premier Handling Solutions

1415 Davis Road

Elgin, IL 60123

Phone: 800-404-2311

Fax: 847-278-2310

URL: phsinc.com