Pallet Inverter Manufacturer

From concept to production, we are committed to developing, building, and maintaining quality solutions that help you reach your goals. Whether your aim is reduced downtime, improved quality, increased efficiency and productivity, enhanced safety, or reduced costs, we’re here to help with professional service and expertise you can rely on.

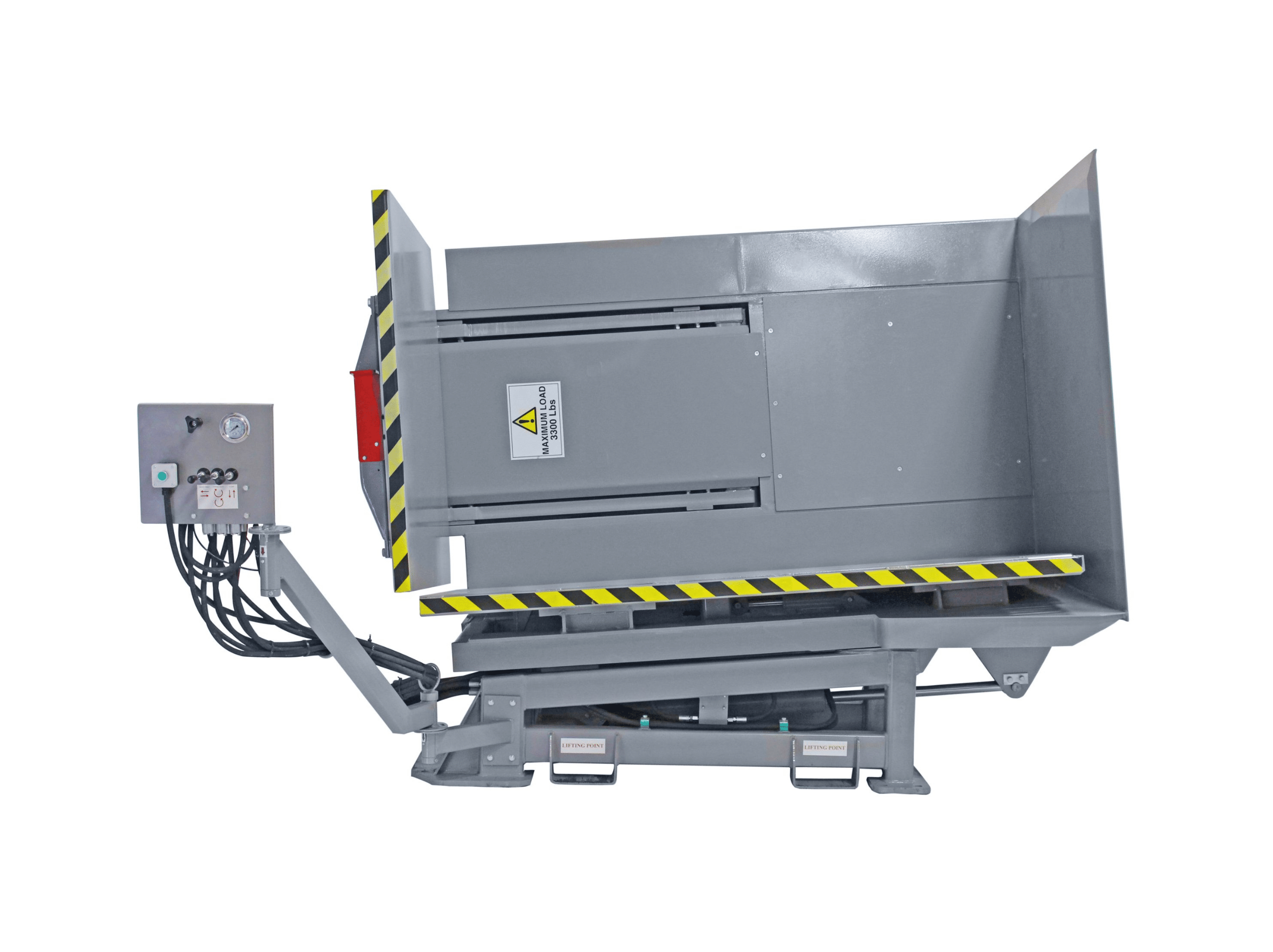

PHS carries equipment such as tippers with a 180-degree rotation capability that makes pallet transfer quick, easy, and safe while reducing product damage. Premier pallet inverters can conquer all of your lifting, tilting, rotating, and transferring hurdles with the widest selection of pallet flippers on the market.

Keep your warehouse intact by effortlessly positioning all types of loads wherever you desire. Our industrial-grade pallet inverters have a surplus of benefits including transferring pallets, replacing broken pallets or damaged goods, and switching shipping skids. Need a custom build to order, rental, or used pallet inverter?

PHS Inc operates across various industries, providing innovative and tailored material handling solutions to our clients.

Primary industries we work with are agriculture, food and beverage, pharmaceuticals, automotive, retail, logistics, chemical, distribution, meat, poultry & seafood, cold storage, cheese & dairy, nutraceutical & cosmetics, bakery, building materials, and more.

Businesses that are looking to streamline their operational processes and improve overall efficiency consider investing in pallet inverters. With our long history of expertise and a reputation for superior quality and service, Premier has become a top choice for businesses across industries.

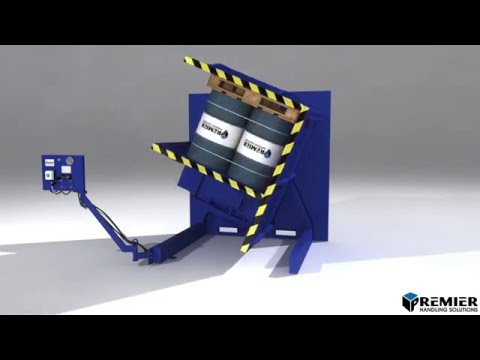

Pallet Inverter Videos

Pallet Inverter Playlist

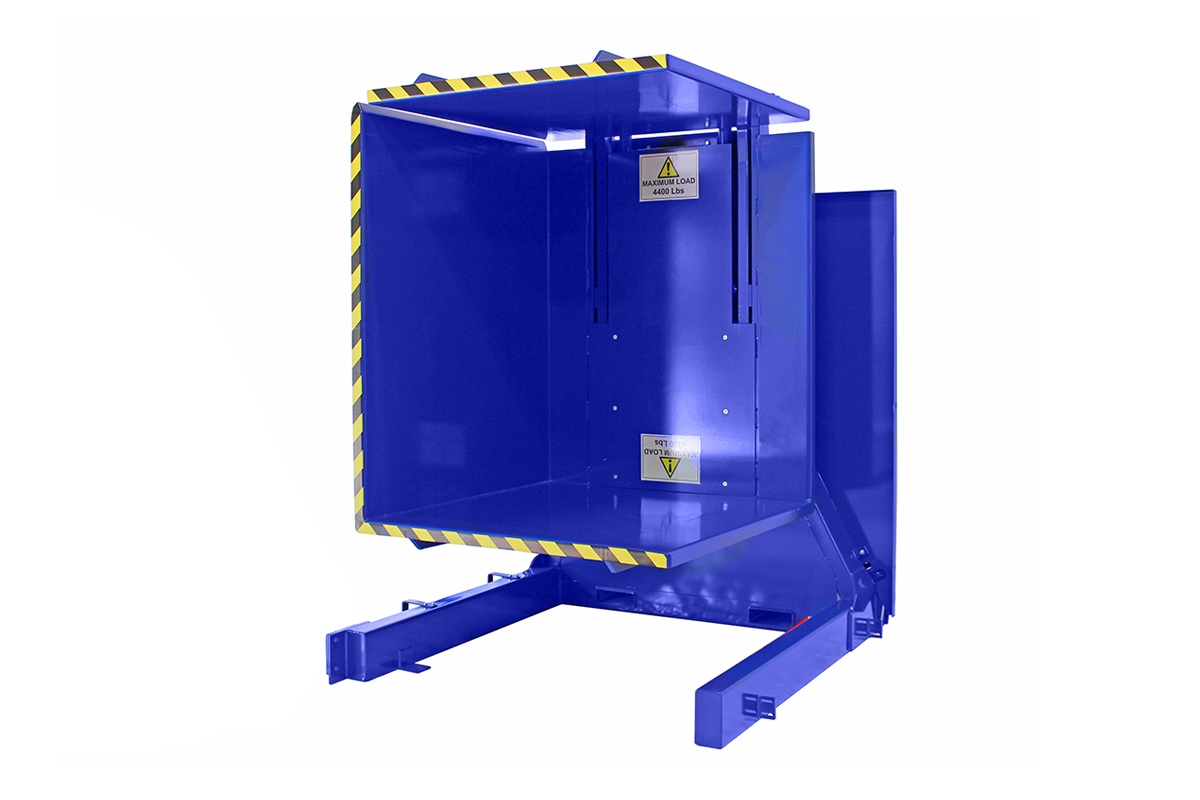

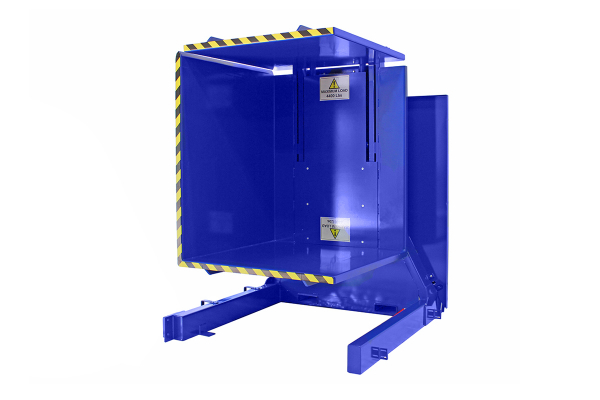

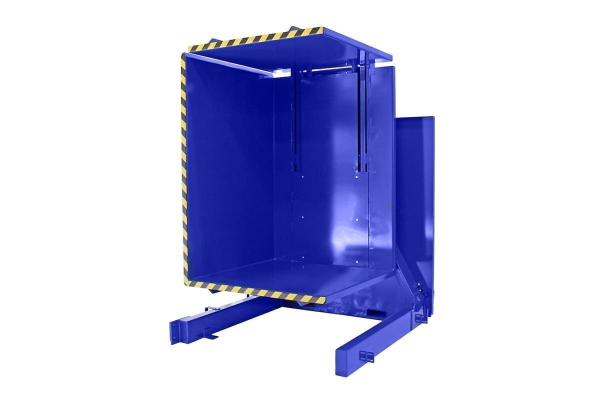

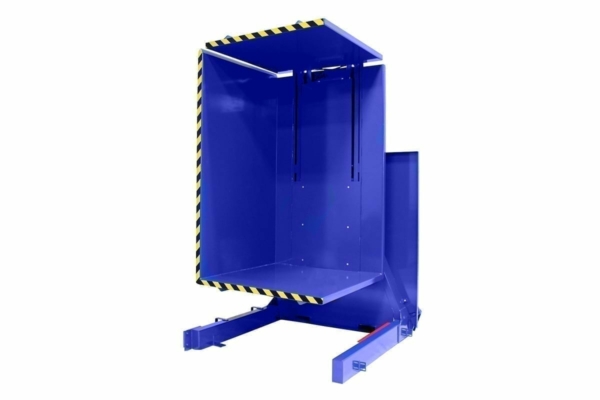

The Premier FS Pallet Inverter (Free Standing) is a cutting-edge piece of equipment designed to streamline the process of transferring goods from damaged or unusable pallets onto new ones. Being a free-standing machine, it’s capable of being placed anywhere in a warehouse facility or logistic center, providing greater flexibility to operators.

One of the most impressive features of this pallet inverter is its ability to rotate loads 180 degrees in a matter of seconds, without the need of manual handling. This enables the machine operator to successfully transfer the goods to the new pallet, including bulk bags or drums. The Premier FS Pallet Inverter can also be utilized to flip loads if required.

Equipped with a free-standing dual clamp system, the Premier FS Pallet Inverter can securely grip any type of pallet load with ease. Unlike other pallet inverters that require additional equipment or attachments, this machine’s dual clamp system is all-inclusive and ready to use straight out of the box.

The Premier FS Pallet Inverter’s intuitive controls provide operators with complete control, making it easy to manipulate pallet loads with precision and speed. This reduces the risk of injuries and accidents in the workplace, making it an ideal investment for companies looking to improve their safety and productivity.

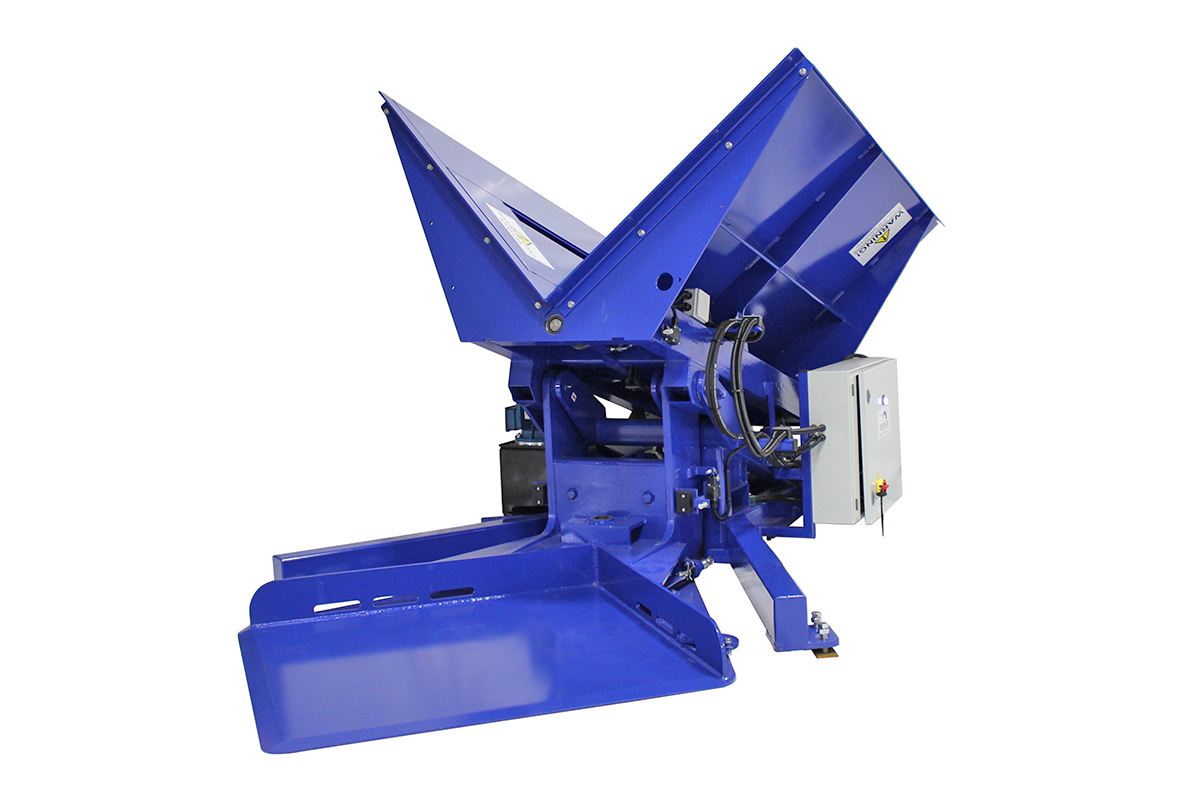

The Premier G95 pallet inverter is a state-of-the-art equipment designed for companies that require efficient and reliable handling of palletized products. This revolutionary device boasts an innovative design that allows it to effortlessly flip over pallets, reducing manual labor and increasing productivity.

In addition to its innovative use of freezer spacers, the Premier G95 Pallet Inverter also boasts advanced features, such as programmable controls, customizable cycles, and automatic safety features. These state-of-the-art features allow for seamless and hassle-free operation, ultimately resulting in higher productivity and reduced operational costs.

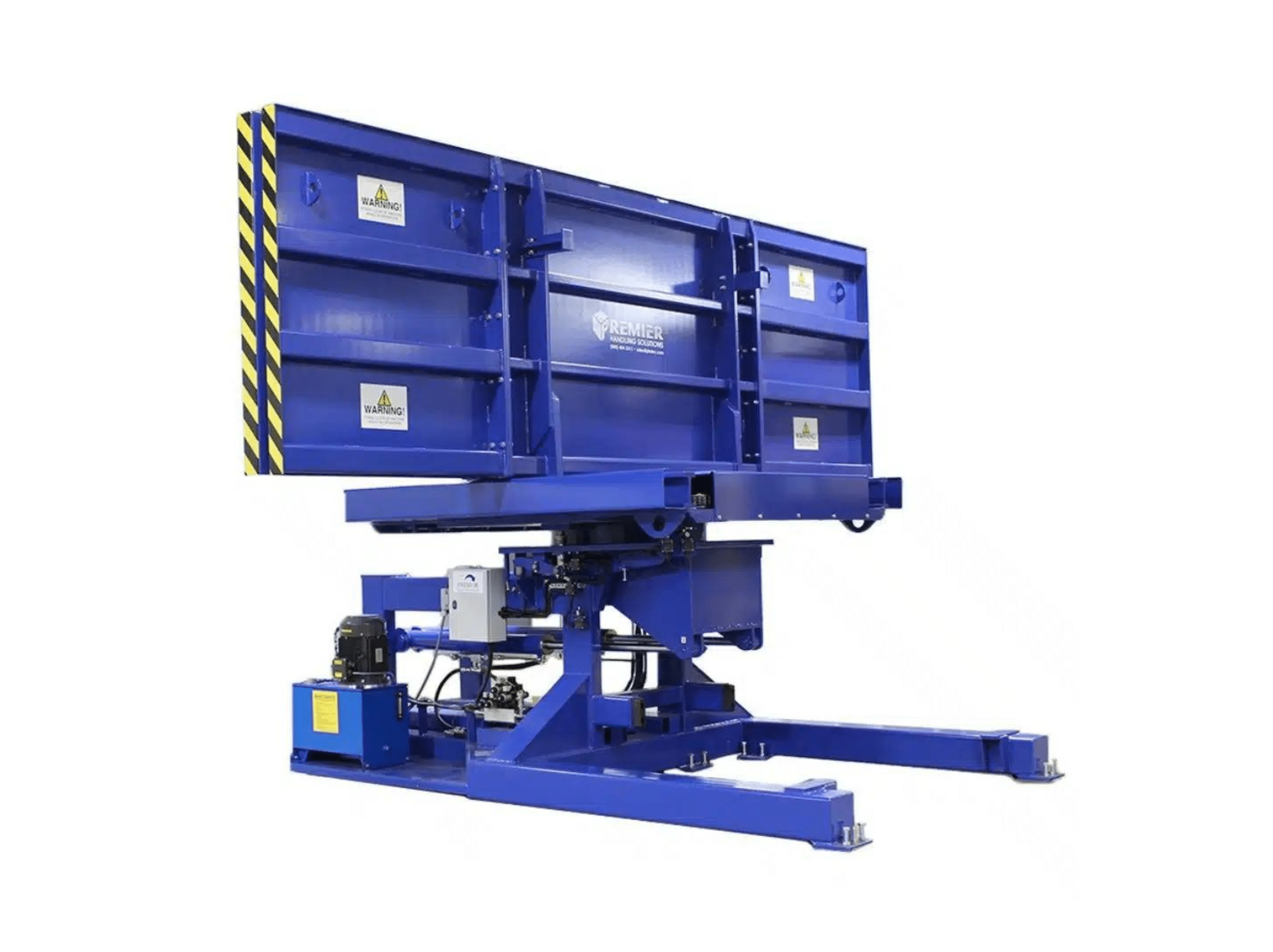

A Premier RR1 pallet inverter is a heavy-duty machine commonly used in warehouses and distribution centers to quickly and efficiently change the orientation of pallets. It is a versatile piece of equipment that has the ability to rotate full pallet loads of goods 180 degrees with ease, making it an essential part of any material handling process.

This innovative machine is specifically designed to handle a wide range of load sizes and types, from food and beverage products to automotive parts and building materials. The Premier RR1 pallet inverter is equipped with automatic clamping arms that securely grip the pallet load, ensuring that it stays in place during the rotation process. This cutting-edge technology results in significant time and labor savings for businesses, as it eliminates the need for manual handling of heavy loads.

Pallet Inverter Advantages

One of the greatest advantages of using Premier pallet inverters is the significant cost savings they can deliver. These pallet inverters reduce the cost of all critical aspects of business execution, making them an indispensable asset for any business. With the ability to handle all types of shipments, from bags and drums to boxes, cartons, and tins, pallet inverters make it easier for businesses to transport products and materials safely and efficiently.

Premier pallet inverters are competitively priced and always keeps ample stock on hand for fast shipping from our Elgin, Illinois location. This means that businesses can order their pallet inverters with confidence, knowing that they will be delivered quickly and with no hassle.