Plastic pallets are often thought of as being more durable and longer-lasting than wood pallets. If you only take into consideration that plastic pallets are more durable and last longer than wood pallets, then an astounding yes, plastic pallets are better than wood. They are also easier to clean and...

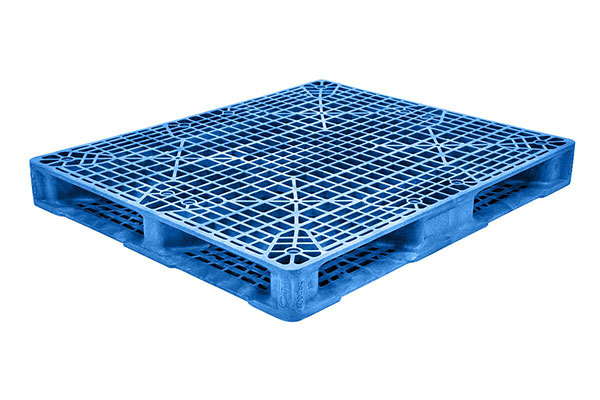

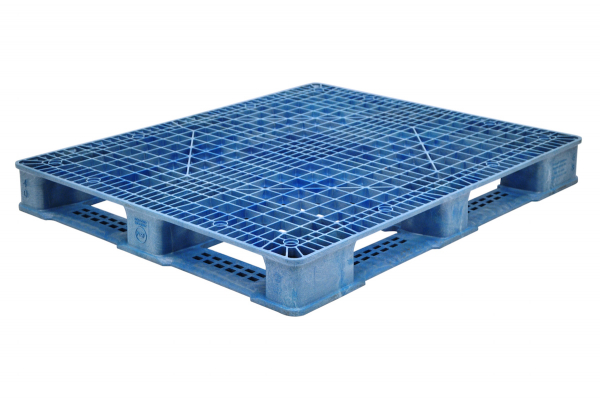

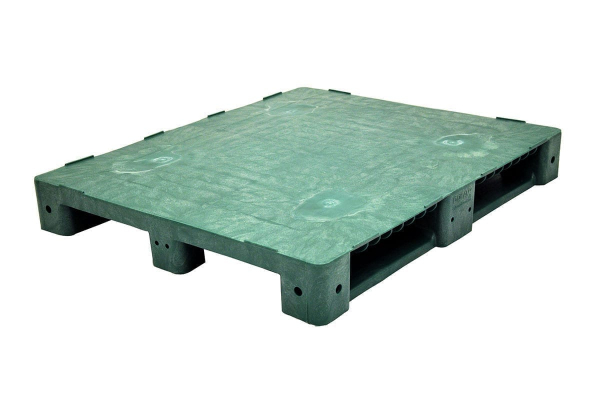

The Best Stackable Plastic Pallets

Premier Is A Leading Stackable Pallet Manufacturer

Stackable plastic pallets are a popular choice for businesses looking to improve their logistics operations. They offer many advantages over other types of pallets, such as wooden pallets, and can help businesses save time and money while also improving safety and efficiency.

One of the key benefits of stackable plastic pallets is their ability to be stacked securely, which allows businesses to optimize their storage and transportation space. This is especially important for businesses with limited storage space or those looking to maximize their truck or container space. With stackable plastic pallets, businesses can stack pallets higher and more securely, which reduces the risk of damage to goods during transport and helps to prevent accidents and injuries.

Another benefit of stackable plastic pallets is their durability and resistance to damage. Unlike wooden pallets, which can become damaged and unsafe over time, plastic pallets are designed to withstand the rigors of transportation and storage. They are resistant to moisture, chemicals, and impact, and can withstand repeated use without breaking or warping. This makes them an ideal choice for businesses with high-volume operations or those that require pallets to be used repeatedly.

In addition to their durability, stackable plastic pallets are also easy to clean and maintain. They can be quickly and easily cleaned with a pressure washer or other cleaning equipment, and they do not absorb moisture or odors like wooden pallets. This helps to prevent the growth of bacteria and other contaminants, which is especially important for businesses in the food and beverage industry.