Pallet Racking

Premier Handling Solutions stands out as a trusted leader in the material handling industry, with a commitment to excellence that has earned us the loyalty of thousands of clients worldwide.

PHS provides heavy-duty pallet racking to help increase your warehouse storage space. We carry 4 custom industrial racking styles from edge, selective, supported, and push-back rack systems. Contact a sales representative today for more details. 1-800-404-2311.

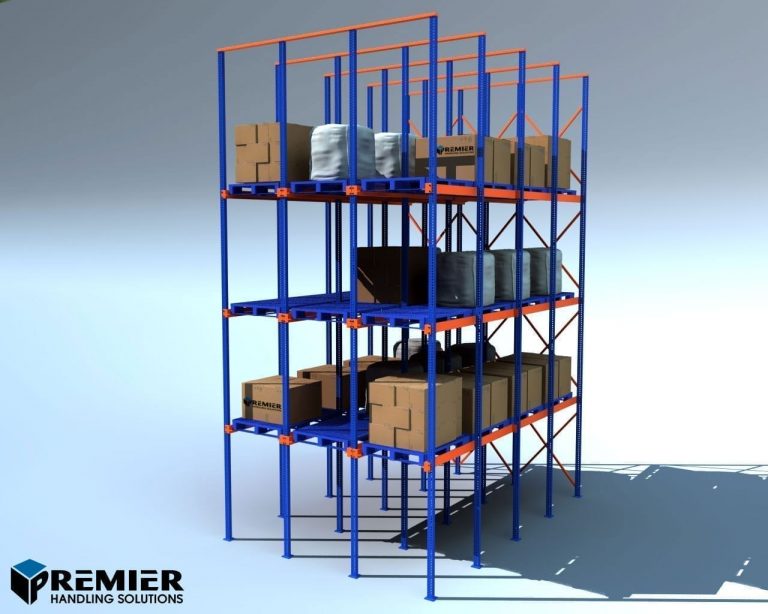

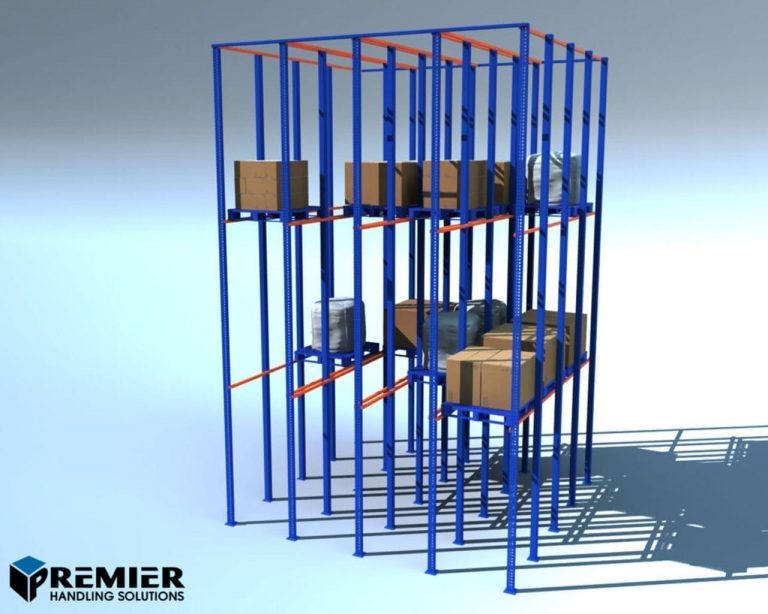

Our Pallet racks can be purchased at a single level or a multi-level storage system. They are utilized to support at a high stacking height. Premier Pallet rack systems are a rudimentary component of any warehouse, distribution, storage facility, or any variety of material handling operations. Our Pallet racks allow convenient access to your stored materials. Premier Pallet rack systems augment your facility to conserve maximum space. Enhance your storage facility even further with Premier Wire Containers.

Selective Racking

Selective Racking is the most common and versatile pallet racking style in the industry. Selective racking allows immediate access to every load without requiring you to move around loads. Selective racking works well for businesses that operate on a FIFO (First In First Out) system.

There are two main types of Selective Racking:

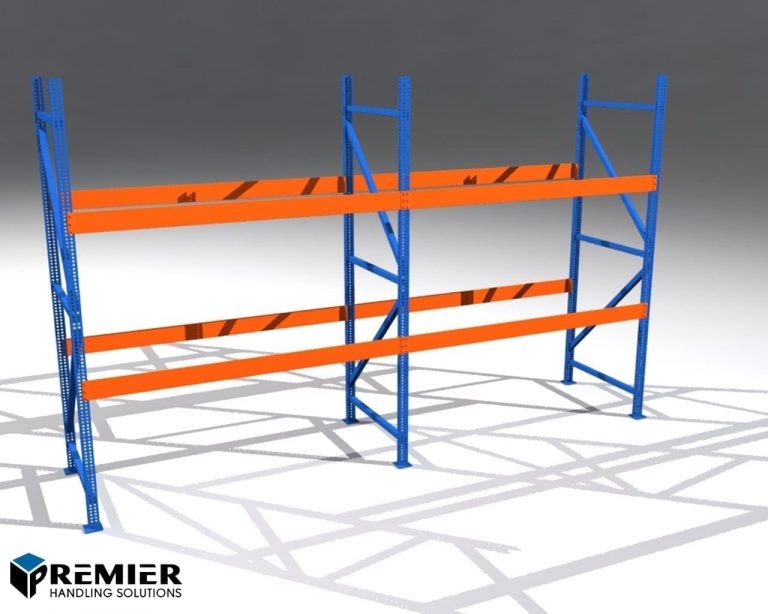

Single Deep Selective: Single selective racking is the most common type of pallet racking and is one pallet deep. Although single deep is flexible and low cost, it comes at the cost of space utilization.

Double Deep Selective: Double deep selective racking provides a benefit of space utilization as two single selective racks are placed back to back allowing you to store two pallet loads deep.

Push Back Racking

Push-Back Racking has a singular loading area that allows you to load a pallet while simultaneously pushing the previous pallet towards the back of the rack. Push-Back racking can be configured for FIFO (First In First Out) load management if there are separate loading and unloading zones, or LIFO (Last In First Out) load management if loading and unloading zones are the same.

There are two main types of Push-Back Racking:

Push-Back with shuttles: Pallets are loaded onto shuttles which move along rails with a slight incline.

Push-back with Rollers: The pallets are loaded onto a a bed of rollers that fixed to the racks with a slight incline.

Edge Racking

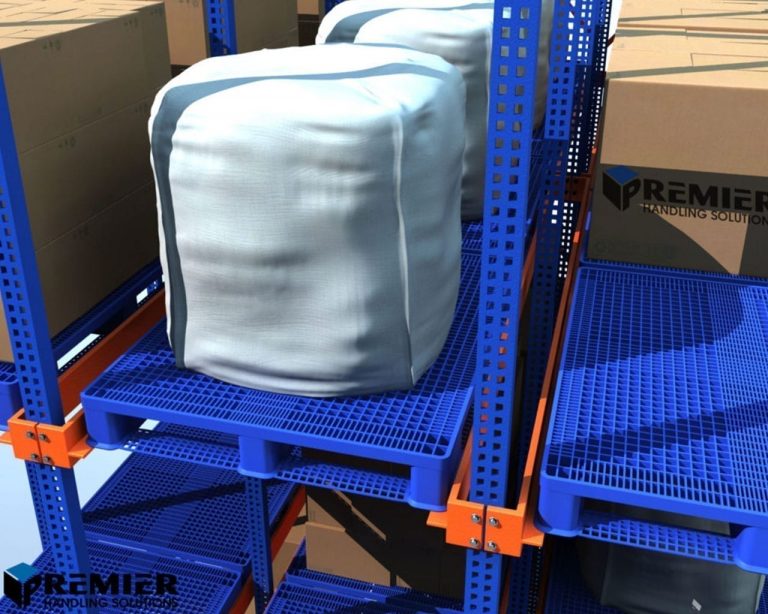

Edge Racking refers to pallet racking in which the pallets are provided no central support and the pallets are supported on only two edges of the pallet. Before considering edge racking, make sure you look at the racking capacity of the pallet you are looking to rack as it is usually referencing edge racking capacity. This type of racking is typically racked on the 48″ sides of a standard 40″ x 48″ pallet but can also be racked on the 40″ sides as well, such as a selective unsupported racking.

There are two main types of Edge Racking:

Drive-In Rack: The pallets are loaded by driving through the racks and most often racked along the 48″ edges of the pallet.

Standard Selective Racking: Pallets are loaded from the front of the rack side by side along the 40″ edges of the pallet.

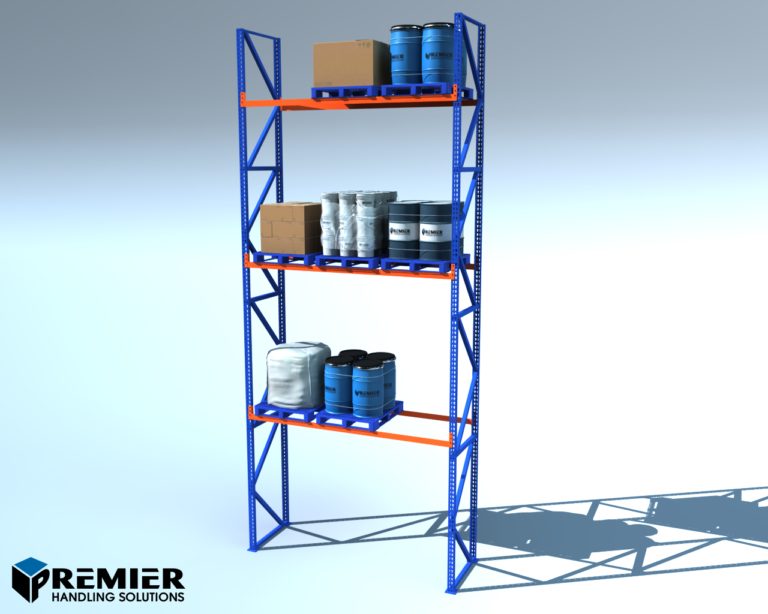

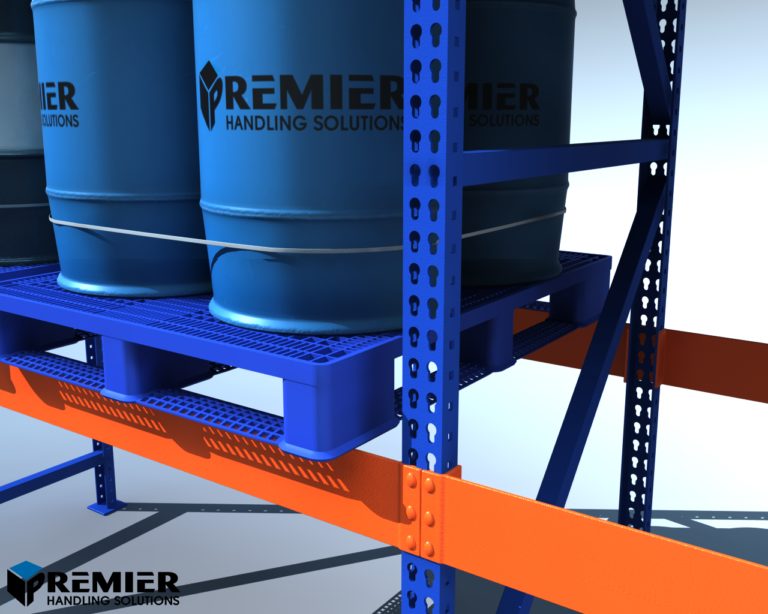

Supported Racking

Supported racking is Selective Racking with central support to safeguard misaligned pallets and increase the structural integrity of the pallet. This will also minimizing deflection (degree to which a structural or roll-formed component is bent or displaced under a load).

There are three main types of supports for supported racking:

Flange Supports: Flange supports fit over the top of the front and back step beams.

Flush Supports: These types of supports flush up to the step beams and leave the face of the step beams completely unobstructed.

Wire Mesh Decking: Wire Mesh Decking is one of the most common support accessories and forms a foundation between beams allowing for a uniform support to the whole pallet load. Although mesh decking is often seen as a flange support it can also be flush.

Contact Form

Please get in contact using the form below...

"*" indicates required fields

Trusted by 10,000+ world-class brands and organizations of all sizes.

Pallet Racking: The Backbone of Warehousing

Ever walked into a warehouse and marveled at the towering shelves neatly stacked with goods? That’s pallet racking for you! It’s like the skeleton of the warehousing world, holding everything together. But what exactly is it, and why is it so crucial?

Understanding Pallet Racking

What is Pallet Racking?

Imagine your bookshelf at home. Now, super-size it, make it sturdier, and you’ve got yourself a basic idea of pallet racking. It’s a storage system designed to stack materials on pallets or “skids.” These racks optimize storage space and ensure easy access to every item, making warehouse operations smooth and efficient.

Types of Pallet Racks

Upright Frames: Think of these as the legs of your bookshelf. They stand tall and support the entire structure. Upright frames determine the height and depth of the pallet rack.

Beams: These are the horizontal supports where the pallets rest. They connect the upright frames and come in various lengths, depending on the width of the rack.

Pallet Rack Accessories

Shelving Options

Beyond the basic structure, there are various shelving options to customize your pallet rack. Wire decking, for instance, provides added support and safety, while pallet supports act as a bridge between beams, offering extra stability.

Safety Accessories

Safety first, right? Accessories like column protectors and guard rails ensure that both the racks and the people working around them are safe. They minimize damage from forklift collisions and other accidents.

Buying Pallet Racks: What to Look For

New vs. Used Racks

On a budget? Used pallet racks might be your best bet. They’re often just as sturdy as new ones but come at a fraction of the price. However, ensure they’re in good condition and meet safety standards.

Heavy-Duty Needs

If you’re storing heavy items, you’ll need heavy-duty racks. These are designed to bear more weight and are built with stronger materials. Always check the weight capacity before making a purchase.

Installation and Safety Tips

Proper Installation

A pallet rack is only as good as its installation. Ensure it’s level, anchored to the floor, and spaced correctly. It might be tempting to DIY, but hiring professionals can save you a lot of headaches (and potential accidents) in the long run.

Ensuring Safety in the Warehouse

Regular inspections are a must. Check for any signs of wear, tear, or damage. Also, train your staff. They should know the weight limits, how to load and unload correctly, and what to do in case of an emergency.

The Industry’s Dependence on Pallet Racking

From retail to manufacturing, industries rely on pallet racking systems. They maximize storage, improve efficiency, and can be tailored to specific needs. In essence, they’re the unsung heroes of the warehousing world.

Conclusion

Pallet racking isn’t just about stacking goods. It’s about optimizing space, ensuring safety, and boosting efficiency. Whether you’re in the market for a new system or just curious about how warehouses work, understanding pallet racking is key. After all, it’s the backbone of warehousing!

About Premier Handling Solutions

“Industry Proven Solutions”

Premier Handling Solutions is a leading manufacturer that proudly provides American-made machines and tools to material handling and supply-chain industries. We provide warehouse equipment solutions that improve overall productivity, safety, and speed throughout the manufacturing, warehousing, distribution, consumption, storage, and disposal process.

Our products span from pallets, inverters, tippers, wire containers, pallet dispensers, pallet jacks, and lift tables, to safety accessories, hygiene tools, freezer spacers, and beyond. Ship and store products like food and pharmaceuticals safely, with PHS pallets and containers. With Premier Handling Solutions, businesses maximize the use of their warehouse and facility spaces and optimally manage HACCP programs.

PHS products uphold top industry standards and meet required government compliance and regulations.

Quick Menu

Location

Premier Handling Solutions

1415 Davis Road

Elgin, IL 60123

Phone: 800-404-2311

Fax: 847-278-2310

URL: phsinc.com