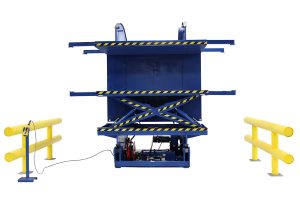

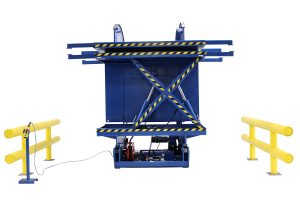

UPENDER INVERTER

The Upender/Inverter with the scissor-type hydraulic operated platform is a highly versatile machine that is designed to perform a wide range of lifting, feeding, accumulating, aligning, transporting, upending, rotating, tilting, and moving operations. All units are electric motor powered with push-button remote control. The units have the load capacity rating typed on a label attached to the sides

of the lift platform.

- Lightweight and low height

- Recyclable

- Low-cost Plastic Pallet

- Impervious to acids, fats, solvents, and odors

- Resists water absorption & bacteria growth

- Consistency dimensionally accurate

- Exempt from ISPM 15 shipping regulations

Trusted by 10,000+ world-class brands and organizations of all sizes.

About Premier Handling Solutions

“Industry Proven Solutions”

Premier Handling Solutions is a leading manufacturer that proudly provides American-made machines and tools to material handling and supply-chain industries. We provide warehouse equipment solutions that improve overall productivity, safety, and speed throughout the manufacturing, warehousing, distribution, consumption, storage, and disposal process.

Our products span from pallets, inverters, tippers, wire containers, pallet dispensers, pallet jacks, and lift tables, to safety accessories, hygiene tools, freezer spacers, and beyond. Ship and store products like food and pharmaceuticals safely, with PHS pallets and containers. With Premier Handling Solutions, businesses maximize the use of their warehouse and facility spaces and optimally manage HACCP programs.

PHS products uphold top industry standards and meet required government compliance and regulations.

Quick Menu

Location

Premier Handling Solutions

1415 Davis Road

Elgin, IL 60123

Phone: 800-404-2311

Fax: 847-278-2310

URL: phsinc.com